Quality Assurance Facilities

Our stainless steel hoses meet BS-6501 (Part-1) 2004 and ISO-10380-2012 standards. We rigorously test for cycle life, burst pressure, bend radius, and flame resistance. Our yield and burst testing system ensures the reliability and safety of our hoses by validating their burst pressure.

Comprehensive Quality Testing for Stainless Steel Hoses

At QUALITY FLEX, our qualified QC engineers carefully check every part of the production process of stainless steel hoses. We have an in-house lab that meets international standards for flexible metallic hoses. Each stainless steel flexible hose assembly is tested with hydraulic pressure 1.5 times its normal pressure before it is sent out, and we also do pneumatic testing when needed. All our steel braided hoses, SS hose fittings, and raw materials are thoroughly inspected to ensure top quality.

Fill the form details below. our support team will get in touch with us.

Conducting Following Tests Regularly

Each hose assembly undergoes hydraulic testing at 1.5 times its working pressure, with pneumatic testing performed as needed. We source all raw materials from reputable manufacturers and subject them to rigorous checks by external inspection agencies for their physical and chemical properties.

Certificates from third-party inspections by independent agencies such as DNV, Lloyds, and BVQI are provided. Additionally, every raw material, from strips to end fittings, is tested through PMI and spectro analysis, as illustrated in the images below.

Types Of Tests

- Flex Fatigue or Cycle Life Test: Evaluates the durability of hoses under repeated flexing to ensure long-term performance and reliability.

- Burst Pressure or Yield Test: Measures the maximum pressure a hose can withstand before failure, ensuring safety and structural integrity.

- Bend Radius Test: Assesses how well the hose maintains its performance when bent to specific radii, preventing kinks and damage.

- Flame Test: Tests the hose’s resistance to flames and high temperatures to ensure safety and compliance with fire-resistant standards.

Certifications and Quality Standards

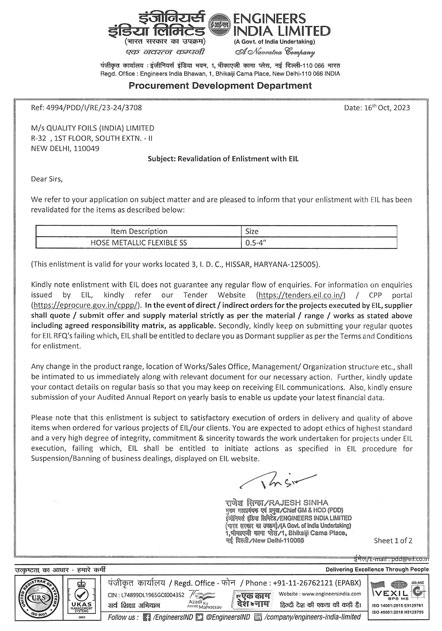

Quality Foils [India] Pvt. Ltd., certified ISO-9001 by TUV SUD South Asia Private Limited, specializes in manufacturing cold rolled stainless steel coils, strips, flexible corrugated hoses (both braided and unbraided), and hose assemblies.