Comprehensive Guide on Flexible Metal Hoses

Flexible metal hoses are used to connect two distant points to transport fluids. While flexible metal hoses may look similar, their size, thickness, and dimensions can be adjusted to suit different needs.

At Quality Flex, we create flexible metal hoses that are customized to reduce vibrations, minimize pipe movements, and lower noise levels. Our hoses are perfect for connecting pipes that don’t line up perfectly or for linking parts of machines that move. They’re also great for equipment that needs to be moved or taken apart frequently.

Our flexible metal hoses are strong, resistant to corrosion, and can handle high temperatures, ensuring they last a long time, even in tough conditions. Choose Quality Flex for durable and high-quality flexible metal hoses made to fit your specific needs.

What is a Flexible Metal Hose?

A flexible metal hose is a type of pipe used to connect two points for fluid transfer, especially where movement or durability is needed. Unlike plastic or rubber hoses, these are made from strong, corrosion-resistant metal alloys like stainless steel, bronze, and Inconel, and can withstand high temperatures.

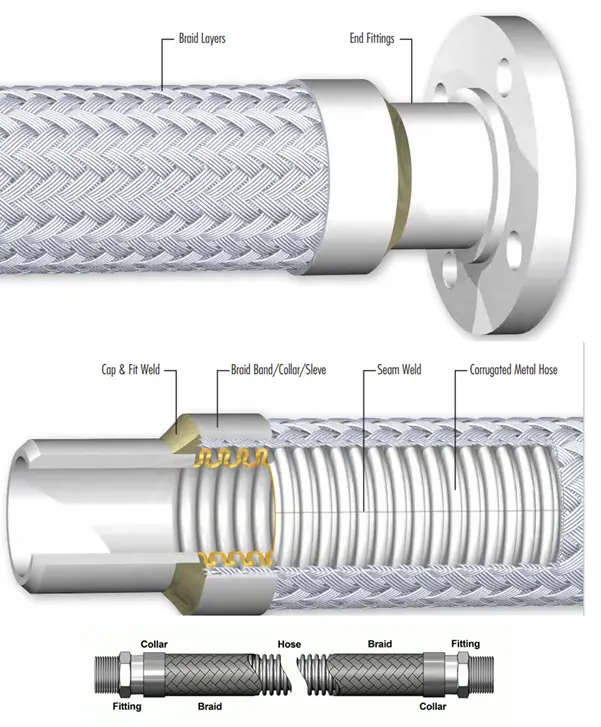

These hoses are consists of below 4 components:

- Corrugated Tubing: Provides flexibility and pressure handling.

- Braid: Enhances pressure capacity and longevity.

- Braid Collar: Secures the tubing and braid, preventing damage.

- End Fittings: Customizes the hose for various applications.

Flexible metal hoses are essential in industries like oil & gas, chemical processing, and machinery, where they absorb vibrations, connect misaligned pipes, and perform reliably under tough conditions.

Types of Metallic Flexible Hoses

Metallic flexible hoses are manufactured in two primary styles: corrugated stainless steel hoses and interlock hoses. Each type is designed to meet specific application needs, offering distinct advantages in terms of flexibility, durability, and pressure handling

Corrugated Stainless Steel Hoses

Corrugated hoses are constructed with a series of ridges or corrugations along their length, which allow them to flex without compromising strength. These hoses are often reinforced with braid wrappings on the outer surface to resist longitudinal pressure stress and prevent squirming under internal pressure. The braid also protects the hose from external damage, ensuring longevity and durability. Corrugated hoses are ideal for transporting a wide range of gas and liquids, provided they are compatible with the hose material.

Interlock Hoses

Interlock Hoses Interlock hoses are made by spirally winding a pre-formed continuous metal strip, with the edges interlocking to form a hose. This construction creates a flexible hose that is robust and resistant to mechanical stress. Interlock hoses can be fitted with a directional flow liner to enhance performance, and they are available in various alloys, including galvanized and stainless steel. They come in a range of sizes, lengths, and end fitting configurations, making them suitable for diverse industrial applications.

Both types of metallic flexible hoses offer unique benefits depending on the requirements of the application, ensuring reliable performance in challenging environments.

Check out our product range of stainless steel flexible hose & how they meet your business needs!

Key Considerations for Installing Flexible Metal Hoses

Proper installation is crucial for the longevity and performance of flexible metal hoses. At Quality Flex, we prioritize precision in every installation. Here are key guidelines:

- Avoid Twisting: Ensure the hose flexes only in the plane of bending to prevent stress.

- Sufficient Length: The hose should be long enough to handle offset and movement without strain.

- Space: Allow enough room for the hose to fit comfortably, avoiding compression or stretching.

- No Sharp Bends: Follow the vendor’s technical data to recommend minimum bend radius to maintain hose integrity.

- Maintain Bend Radius: Consistently adhere to the minimum bend radius during installation.

Advantages of Flexible Metal Hoses

- Wide Temperature Range: Handles -200°C to +650°C.

- Thermal Expansion: Compensates for expansion and contraction in piping.

- Strong & Lightweight: Combines durability with easy handling.

- Fire & Moisture Resistant: Long-lasting protection against elements.

- Corrosion & Abrasion Resistant: Durable against damage and wear.

- Vibration Absorption: Connects misaligned piping and reduces vibration.

- Flexible Installation: Ideal for rigid piping in tough-to-reach areas.

Uses of Flexible Metal Hoses

- Gardening: Perfect for watering plants or connecting to sprinklers.

- Agriculture: Ideal for drip irrigation to efficiently water crops.

- Air Supply: Used to transport air from compressors or tanks.

- Fuel Transport: Safely carries fuel in various settings.

- Firefighting: Essential for delivering water to fire sites.

- Chemical & Medical Use: Moves liquid chemicals or gas with precision.

- Heat Tracing: Effective in maintaining temperatures in heat tracing systems.

- Oil Industry: Handles high-pressure liquids in oil-related operations.

Conclusion

Flexible metal hoses are essential in many industries because they are durable, flexible, and can withstand tough conditions. Whether you need to move fluids, reduce vibrations, or connect pipes that don’t align perfectly, Quality Flex offers custom solutions to meet your needs. We focus on quality and precision in both making and installing our hoses, ensuring they last a long time, even in challenging environments. Choose Quality Flex for all your flexible metal hose needs—built to last, designed to perform.

FAQ

These hoses are made from corrosion-resistant metals like stainless steel, bronze, and Inconel, allowing them to withstand high temperatures and harsh environments.

Proper installation includes avoiding twisting, ensuring the hose is long enough, providing adequate space, and maintaining the recommended bend radius.

They can handle extreme temperatures, resist corrosion, absorb vibrations, and compensate for thermal expansion. They are also strong yet lightweight, making them easy to install.

Quality Flex offers corrugated stainless steel hoses and interlock hoses, each designed for specific needs with durability and flexibility.

Yes, Quality Flex customizes hoses to meet your specific needs, including variations in size, thickness, and end fittings.