SS Flexible Hoses Applications

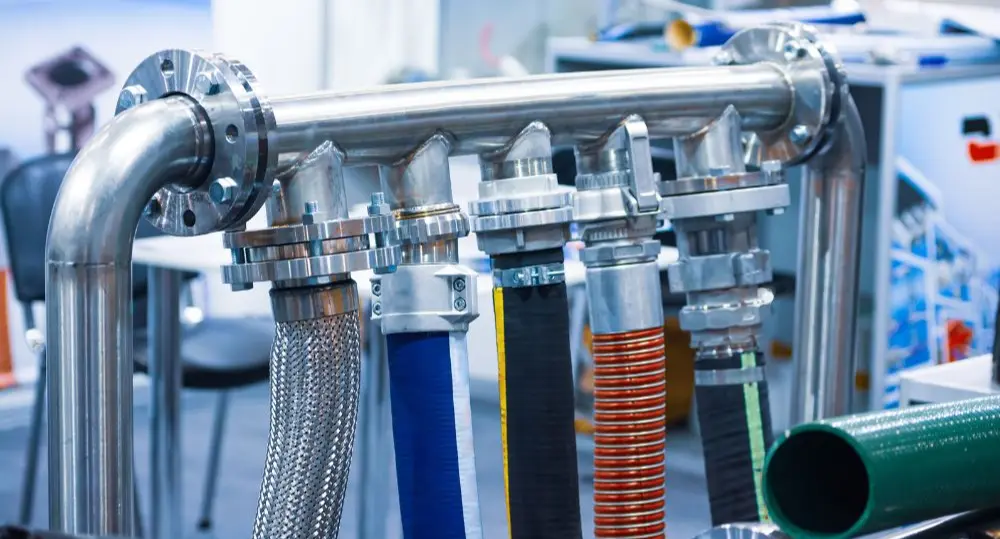

SS Flex Hoses Components

Corrugated Tubing

The core of an ss flexible hose is corrugated tubing, providing flexibility and pressure resistance. Made from corrosion-resistant stainless steel, it’s ideal for transporting various fluids. It bends without cracking and has a Minimum Dynamic Bend Radius (MDBR) to prevent damage.

Braid

The braided outer layer of steel hoses reinforces the tubing, increasing its pressure capacity and preventing elongation. It supports high-pressure use, and multiple layers can enhance strength. The braid design also extends the hose’s cycle life, ensuring durability in repeated bending.

Braid Collars

These are essential components for attaching the corrugated tubing to the braid. They secure the SS hose assembly, ensuring the braid stays in place and distributes bending stresses evenly across the hose.

End Fittings

End fittings allow the stainless steel flexible hose to be attached to other piping or equipment. Options for customization based on the application include size, alloy material, and pressure handling requirements.

Installation Precautions for Stainless Steel Flexible Hose

- Inspection: Before use, inspect the hose for visible damage, including kinks, broken braids, or crush marks.

- Axial Movement: Avoid axial movement during installation to prevent hose damage. Also, ensure that bends conform to the specified bend radius.

- Leak Testing: Always test the hose for leaks before installation. Compliance with international standards is crucial to ensure safety and durability.

Key Applications of Stainless Steel Flexible Hoses

Pharmaceutical Industry

In the pharmaceutical industry, stainless steel flexible hoses are essential for transporting liquids and gas where hygiene is most important. The stainless steel flex hoses offer excellent resistance to chemical corrosion and ensure the purity of substances during manufacturing processes. Their flexibility allows easy installation, while the smooth inner walls help maintain flow efficiency, preventing contamination.

Chemical Industry

The chemical industry mainly uses ss flexible hoses to transport various aggressive chemicals, acids, and solvents. Due to their robust construction, stainless steel flexible hoses can withstand high temperatures and pressures to be used for applications. The corrosion resistance provided by these hoses ensures long service life, reducing the need for frequent replacements in harsh environments.

Paper Plants

Paper plants use stainless steel flex hoses for handling steam, hot water, and chemicals during the paper manufacturing process. These hoses ensure the safe transfer of fluids while maintaining high efficiency under demanding conditions. Their flexibility and ability to handle high-pressure applications make them perfect for complex machinery and piping layouts in paper production.

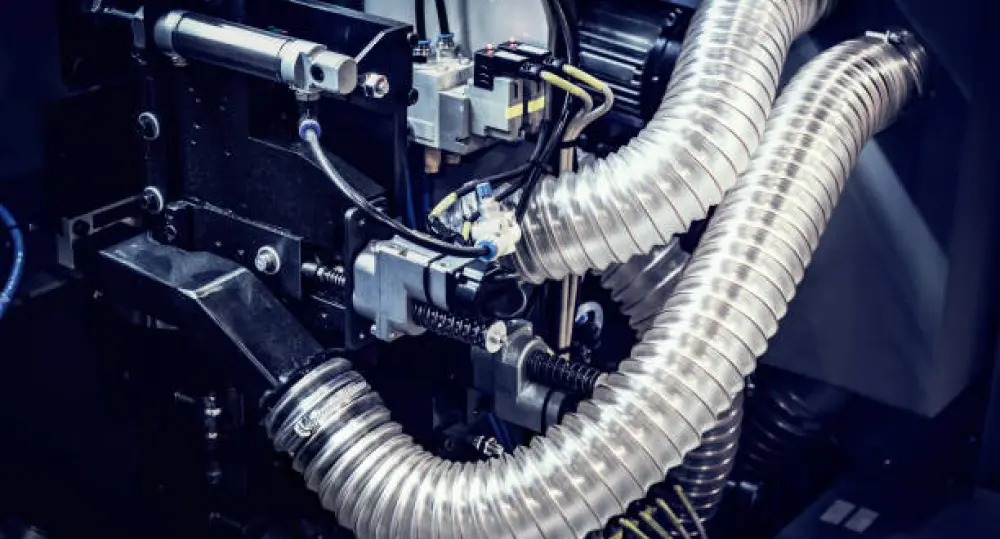

Automotive Industry

In the automotive sector, ss flex hoses are crucial for fuel lines, brake lines, and exhaust systems, where flexibility and high heat resistance are necessary. The stainless steel construction allows the hoses to perform reliably under the high temperatures. Their ability to handle high pressures ensures safe fluid transfer, increasing the overall performance of the vehicle.

Nuclear Installations

Safety is a top priority in nuclear installations, and stainless steel flexible hoses play a vital role in fluid transfer systems that operate under high pressure and temperature conditions. These hoses are used in cooling systems, chemical processing units, and radiation shielding environments, where durability and corrosion resistance are critical for preventing failures and maintaining operational safety.

Fertilizer Industry

The fertilizer industry benefits from ss flexible hoses due to their ability to handle corrosive chemicals and maintain flexibility in challenging conditions. The hoses are often used to transport liquid fertilizers and other chemical compounds during production, ensuring smooth operation and reducing maintenance costs. Their strength and resistance to corrosion extend the life of the equipment used in this industry.

Customization and Pressure Drop Calculations

Stainless steel flex hoses can be customized to suit specific requirements, such as length, pressure rating, and fitting types. Additionally, understanding the pressure drop across the hose length is essential for optimal system design.

Conclusion

Stainless steel flexible hoses have become an indispensable component in industries such as pharmaceuticals, chemicals, paper production, automotive, nuclear, and fertilizers. Their durability, flexibility, and ability to withstand extreme conditions make them the preferred choice for transporting liquids and gas in these demanding applications. By ensuring the correct selection and installation, stainless steel flex hoses offer a long-lasting, reliable solution for fluid handling systems.

By leveraging the unique properties of ss flexible hoses, industries can enhance operational efficiency, reduce downtime, and ensure safety in fluid transfer systems.