Fill in the form details below. Our support team will get in touch with you.

What are Stainless Steel Expansion Joints?

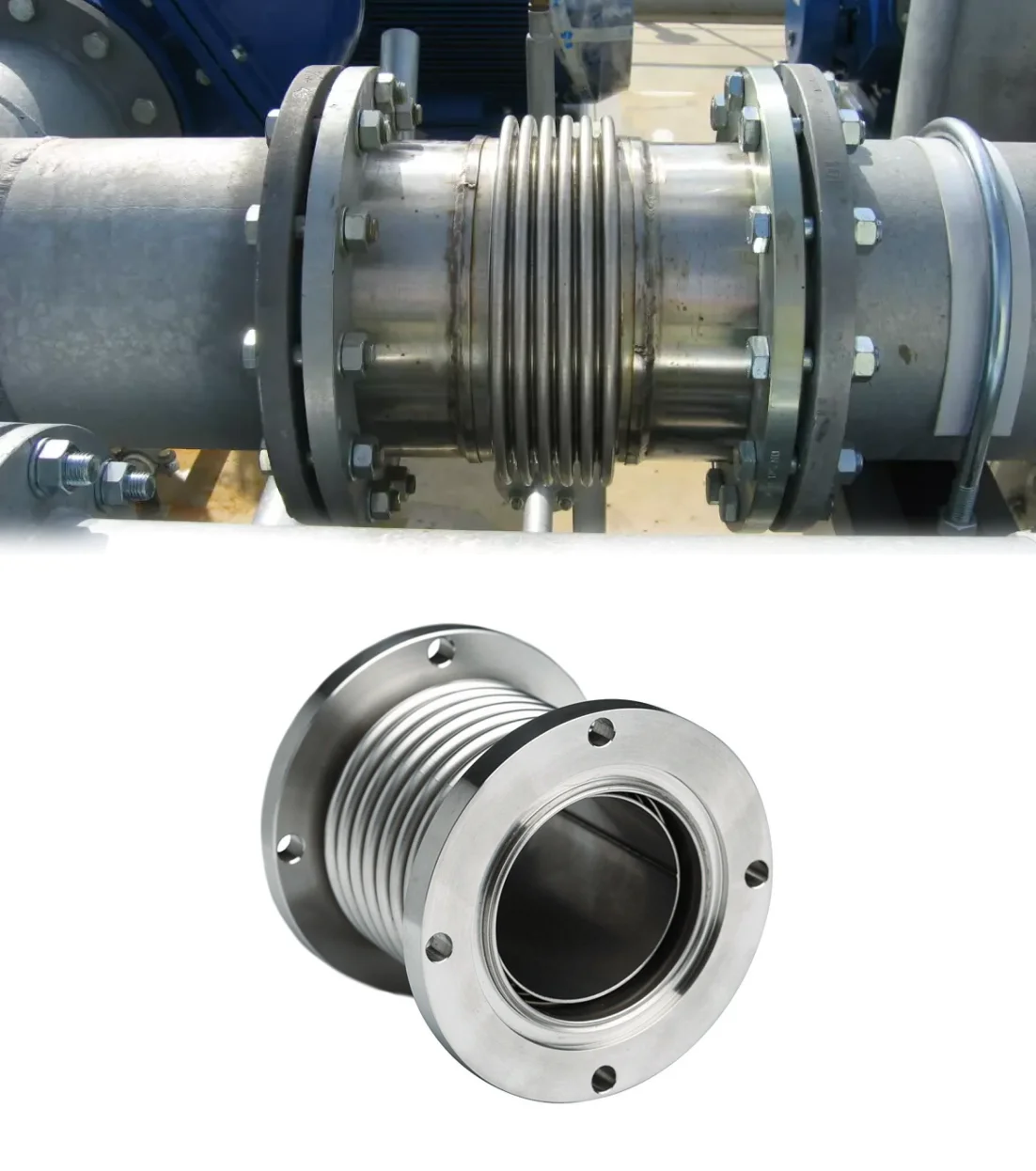

Stainless steel expansion joints are important components in modern piping systems, offering flexibility and durability to accommodate temperature-related expansion and contraction. These SS expansion joints, also called SS expansion bellows, are especially effective in systems with high-temperature fluctuations. By absorbing pipe movements and compensating for thermal expansion, they prevent stress and potential damage within the piping systems.

The unique corrugated design of stainless expansion joints to flex under pressure, providing a solution for vibration isolation in systems with pumps, motors, compressors, or turbines. This flexibility makes them ideal for industrial applications where rubber joints are insufficient. The bellows’ corrugation is specifically engineered to absorb axial, lateral, and angular movements based on system demands.

To handle high-pressure applications, these SS expansion bellows are made from premium materials like grade 321 or 316L stainless steel. They are typically reinforced with anchors, tie rods, hinges, or gimbals, which provide additional support by absorbing the thrust force. SS expansion joints are designed for longevity and noise reduction across various industrial applications.

SS Expansion Joint Manufacturer - Quality Flex

As a leader in the flexible piping industry, Quality Flex specializes in manufacturing stainless steel hoses, stainless steel braided hoses along with SS expansion joints that are mainly used across various industrial applications. Our stainless steel expansion joints are expertly designed to manage thermal expansion, absorb vibrations, and withstand extreme pressure and temperature variations offering long-lasting reliability.

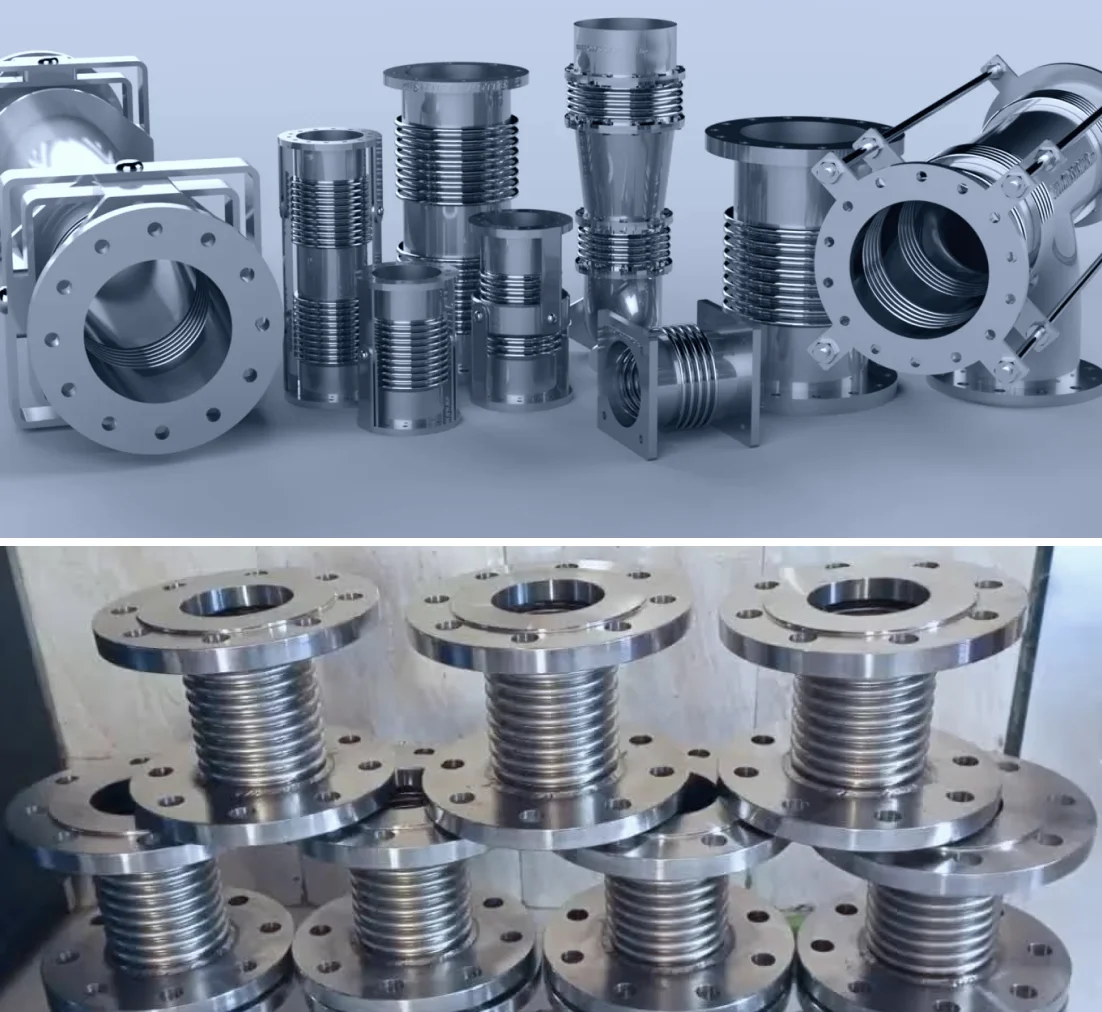

Our stainless expansion joints are built from high-grade materials, including stainless steel 304 and 316L, offering superior corrosion resistance and durability. Quality Flex also customizes designs based on specific client needs, providing single-bellows, pressure-balanced types, and more. Each product is rigorously tested in-house to ensure it meets the highest safety and quality standards before delivery.

As trusted Stainless Steel Expansion Joints Suppliers, we use advanced construction techniques to produce bellows that are lightweight yet robust, capable of absorbing axial, lateral, and angular movements under varying pressures. Each expansion joint is crafted from stainless steel strips welded to form thin-walled tubes, making them diffusion-tight and resistant to chemical wear, which ensures longevity even in aggressive environments.

Our SS expansion joints provide a secure seal, reducing the risk of leaks and maintaining pressure safety. This focus on operational safety is critical in high-stakes industries like oil and gas, where maintaining secure piping systems is essential. Quality Flex offers both standard and custom-designed stainless steel expansion joints, including single-bellows and pressure-balanced types.

Key Features of Quality Flex SS Expansion Joints

Enhanced Corrosion Resistance

Our stainless steel expansion joints are highly resistant to corrosion.

Temperature Endurance

With a temperature range from cryogenic levels up to 600°C, our stainless steel expansion bellows are well-suited for applications involving significant thermal fluctuations.

Reliability and Safety

Our SS expansion joints are designed with secure seals, minimizing leakage points and ensuring pressure stability for safer operations in critical systems.

High-Pressure Capability

Braided stainless hoses are reinforced for handling high-pressure environments, making them ideal for both dynamic and static conditions.

Reduced Maintenance and Compact Design

ality Flex’s ss expansion bellows require minimal upkeep, contributing to cost savings and operational efficiency over time.

Want to discuss your requirements with our experts? Contact Us Now!

Types of Stainless Steel Expansion Joints

SS Expansion Bellow

Slip Joints

Axial Expansion Joints

These stainless expansion joints handle linear movements along the pipe’s axis and absorb some angular movements. They are perfect for applications where longitudinal expansion needs to be managed.

Lateral Expansion Joints

Universal Expansion Joints

Angular Expansion Joints

Pressure-Balanced Expansion Joints

Proper Installation and Maintenance of Expansion Joints

-

Installation: Handle SS expansion joints with care to avoid damage. Ensure proper alignment, stay within movement limits, and install inner sleeves in the correct flow direction. Remove any transport supports after installation.

-

Pre-Service Checks: Verify that each stainless steel expansion joint is correctly positioned and oriented, confirm all supports are removed, and check alignment.

-

Pressure Testing: Inspect for leaks or pressure loss, ensuring that all components of the stainless expansion joint are stable and secure.

-

Maintenance: Regularly inspect SS expansion bellows for unrestricted movement, vibration, corrosion, loose parts, or debris.

-

Fixed Points and Guides: Segment the pipeline into manageable sections and set fixed points at directional changes and between pipe sections for stability.

Benefits of SS Expansion Joints

Thermal Expansion Management

SS expansion joints are designed to absorb thermal expansion and contraction in piping systems, preventing stress and potential damage. Stainless steel expansion joints are allowing systems to handle temperature changes smoothly and maintain structural integrity.

Vibration and Noise Reduction

Stainless steel expansion bellows effectively reduce vibrations and noise, protecting the equipment by absorbing movements and isolating vibrations with heavy machinery and dynamic processes.

Durability and Corrosion Resistance

Enhanced Flexibility and Versatility

Reliability and Safety

Minimal Maintenance Requirements

Application of Stainless Expansion Joints

Oil and Gas Sector

Chemical Processing Plants

Stainless expansion joints offer essential flexibility and corrosion resistance, withstanding continuous exposure to corrosive chemicals and temperature fluctuations, to increase the lifespan of critical piping systems.

Chemical Processing Plants

Stainless expansion joints offer essential flexibility and corrosion resistance, withstanding continuous exposure to corrosive chemicals and temperature fluctuations, to increase the lifespan of critical piping systems.