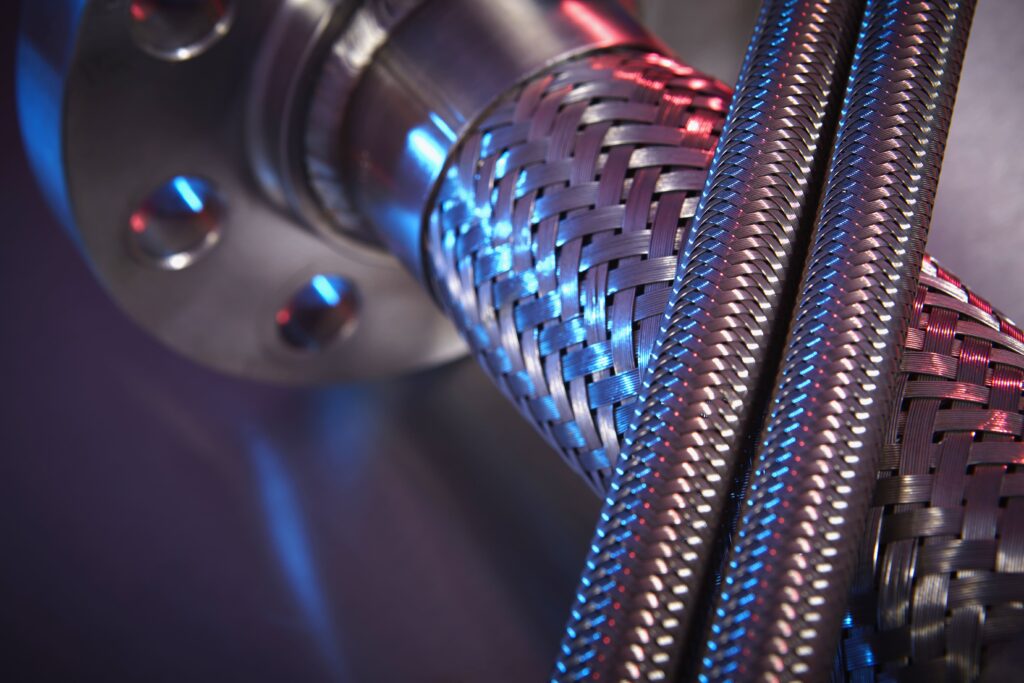

Stainless Steel Hoses

Quality Flex offers premium stainless steel hoses for a wide range of industrial applications, including oil, gas, steel plants, and manufacturing. Our SS hoses are designed to meet top industry standards like BS:6501 Part-1 2004 and IS:10380, ensuring durability, safety, and reliability for fluid and gas transfer. As a leading stainless steel hose manufacturer, we specialize in designing high-pressure stainless steel hoses to withstand extreme temperatures (-200°C to +650°C), fatigue, and high-pressure conditions, offering a long service life.

We manufacture corrugated stainless steel hoses and braided SS hoses using premium stainless steel grades such as AISI 304, 321, and 316L, ensuring excellent corrosion resistance and flexibility. Our SS hoses are designed to resist bending, twisting, and absorbing vibrations, etc. The annular corrugated hose body provides flexibility and a pressure-tight core, while our highly flexible close pitch hoses cater to special applications.

Fill in the form details below. Our support team will get in touch with you.

Corrosion Resistance

Our stainless steel hoses are resistant to corrosion, making them ideal for use in harsh environments.

Temperature Resistance

Suitable for operations from -200°C to +650°C.

Withstand extreme temperatures, offering a reliable solution for both high-heat and low-temperature applications.

High-Pressure Capability

Braided stainless hoses are reinforced for handling high-pressure environments, making them ideal for both dynamic and static conditions.

Flexibility

Flexible stainless steel hoses provide excellent movement in confined spaces, because of its corrugated design that ensures optimal flexibility without compromising strength.

Durability

Built for longevity, ensuring cost-effectiveness and reduced maintenance.

Leak-Proof Construction

Our SS hoses prevent leaks, providing assurance in critical industrial applications where safety is important.

Stainless Steel Hoses Manufacturers in India

At Quality Flex, we take pride in being one of the leading stainless steel hoses manufacturers, offering a comprehensive range of high-performance products tailored to the needs of diverse industries, including chemical manufacturing, automotive, petrochemical, and food processing.

Interested in buying highly flexible stainless steel hoses from Quality Flex for your applications?

Flexible vs. Braided Stainless Steel Hoses

-Which One Is Right for You?

|

|

|

| Feature | Flexible Stainless Steel Hoses | Braided Stainless Steel Hoses |

|---|---|---|

| Flexibility | High flexibility for tight spaces | Moderate flexibility with added strength |

| Pressure Capability | Suitable for moderate pressures | Ideal for high-pressure environments |

| Applications | HVAC, plumbing, confined areas | Hydraulic systems, steam lines, high-pressure fluids |

SS Hoses Industrial Applications

High-pressure stainless steel hoses (SS hoses) offering versatility and flexibility to connect machinery efficiently. These hoses are ideal for demanding conditions requiring absolute high safety, resistance to extreme temperatures, vibrations, high pressure, and corrosion.

Applications of SS hoses include cryogenic, fuel transfer and chemical transfer, vacuum systems, super-heated steam, coolant lines, fuel, super-heated steam, hot water and oil burner lines, gases, toxic media, and food products.

Industrial Applications of Steel Hoses

Stainless hoses are perfect for oil and gas, chemical, and manufacturing industries, providing durability and reliability under extreme conditions, including high temperatures and corrosive environments.

Automotive Applications of SS Hoses

Stainless hoses play a crucial role in exhaust systems, fuel lines, and brake systems, offering durability, flexibility, and resistance to heat and corrosion, enhancing vehicle performance and reducing emissions.

Stainless Hoses in Steel Plants Industry

SS hoses, used in blast furnace operations, are designed for air and oxygen supply. They feature double wire braiding, flange connections, and grease-free components for safe and efficient performance.

SS Hoses in HVAC Systems

Stainless hoses ensure efficient fluid flow and thermal expansion handling in HVAC systems, maintaining air quality and preventing moisture-related damage like mold or mildew growth.

Steel Hoses in Aerospace and Aviation

Stainless steel hoses are crucial for connecting fuel lines and rocket engines, offering resistance to deformation, high temperatures, and compatibility with chemicals like cryogenic fuel.

Stainless Steel Hoses Technical Specifications

- Material: Available in SS304, SS316L, and SS321 for various industry needs. SS316L is particularly well-suited for highly corrosive environments.

- Operating Temperature: From (-200°C to +650°C), making these SS hoses versatile for a wide range of temperatures.

- Pressure Handling: Up to 1500 psi for braided stainless steel hoses, ensuring safe operation in both low and high-pressure applications.

Customizable Options for Stainless Steel Hoses

- Fittings: Choose from a variety of SS hose fittings including flanges, threaded connections, and couplings to suit different industry requirements.

- Length & Size: Available in different lengths and diameters to meet your specific needs, including custom solutions for unique applications.

-

SS Hoses Assemblies:

Stainless Steel hoses assemblies consist of a metal hoses, available with or without a braid.We can design and manufacture almost any kind of stainless steel flexible hoses assembly as per specific requirements.

Stainless Steel Hoses Quality Testing

- All stainless hoses are rigorously tested to ensure durability, pressure resistance, and compliance with international standards. Each SS hoses undergoes hydrostatic testing and pneumatic testing to verify integrity and performance.

- Certifications: Certified to ISO 10380 standards for quality assurance, ensuring reliable performance in all operational environments.