— Resources

SS Hydraulic Fittings

High Quality Stainless Steel Hydraulic Fittings

At QualityFlex, leading stainless steel hydraulic fittings manufacturer that offer unmatched durability and performance needed for industrial applications. Our expertise in exporting a wide range of stainless steel hydraulic hoses ensures that each fitting is designed to handle high pressures, providing optimal corrosion resistance in high-pressure hydraulic systems.

Stainless Steel Hydraulic Fittings are essential components that facilitate the connection of hydraulic hoses to various elements such as pipes, tubes etc. These fittings are most important to preventing leaks and allowing smooth fluid flow, changing direction, and mixing different liquids.

Get in touch

Fill the form details below. our support team will get in touch with us.

Material Choices for Stainless Steel Hydraulic Fittings

- SS 304 Hydraulic Fittings: Known for their excellent resistance to high-concentration solutions at temperatures up to 120°F, making them ideal for industries dealing with chemicals and corrosive environments.

- SS 316 Hydraulic Fittings: Offering better resistance to general corrosion and chloride stress-related corrosion cracking, these fittings are stronger at higher temperatures, making them suitable for more demanding applications.

Technical Specification of Stainless Steel Hydraulic Fittings

| Material | SS 304L, SS 304, SS 316L, SS 316, SS 310, SS 316TI (1.4571), SS 347 |

|---|---|

| Design Standard | ISO 8434-1 / DIN 2353 |

| Size Range | L Series – 6L to 42L |

| LL Series – 4LL to 12LL | |

| S Series – 6S to 38S | |

| Equivalent Brands | HY-LOK, PARKER, DK-LOK, HYDAC, STAUFF, VOSS |

| Series | L – Medium Pressure, LL – Low Pressure, S – High Pressure |

| Working Pressure | (Medium) L Series – 100 Bar to 500 Bar |

| (Low) LL Series – 100 Bar | |

| (Heavy) S Series – 200 Bar to 800 Bar | |

| Body Type | Forged, Bar Stock |

| Connections | Weld Nipple to Female Thread, Weld Nipple to Swivel, Weld Nipple to Male Thread, Weld Nipple to Socket Weld, Weld Nipple to Butt Weld, Weld Nipple to 37° JIC, Weld Nipple to 24° Cone |

| Tube to Male Thread, Tube to Swivel End, Tube to Tube, Tube to Adjustable Standpipe, Tube to Female Thread, Tube to Socket Weld, Tube to Butt Weld, Tube to 24° Cone, Tube to JIC 37° | |

| Surface | SS – Short Blasted Finish, Export Bright and Electroplated Finish |

| Temperature | -60°C to 400°C |

| Designator | SS – ASTM A182 / A276 |

Types of SS Hydraulic Fittings

PU Flow Control Valve

Hydraulic Plug In Elbow

Pneumatic Male Branch Tee

Hydraulic Plain Elbow

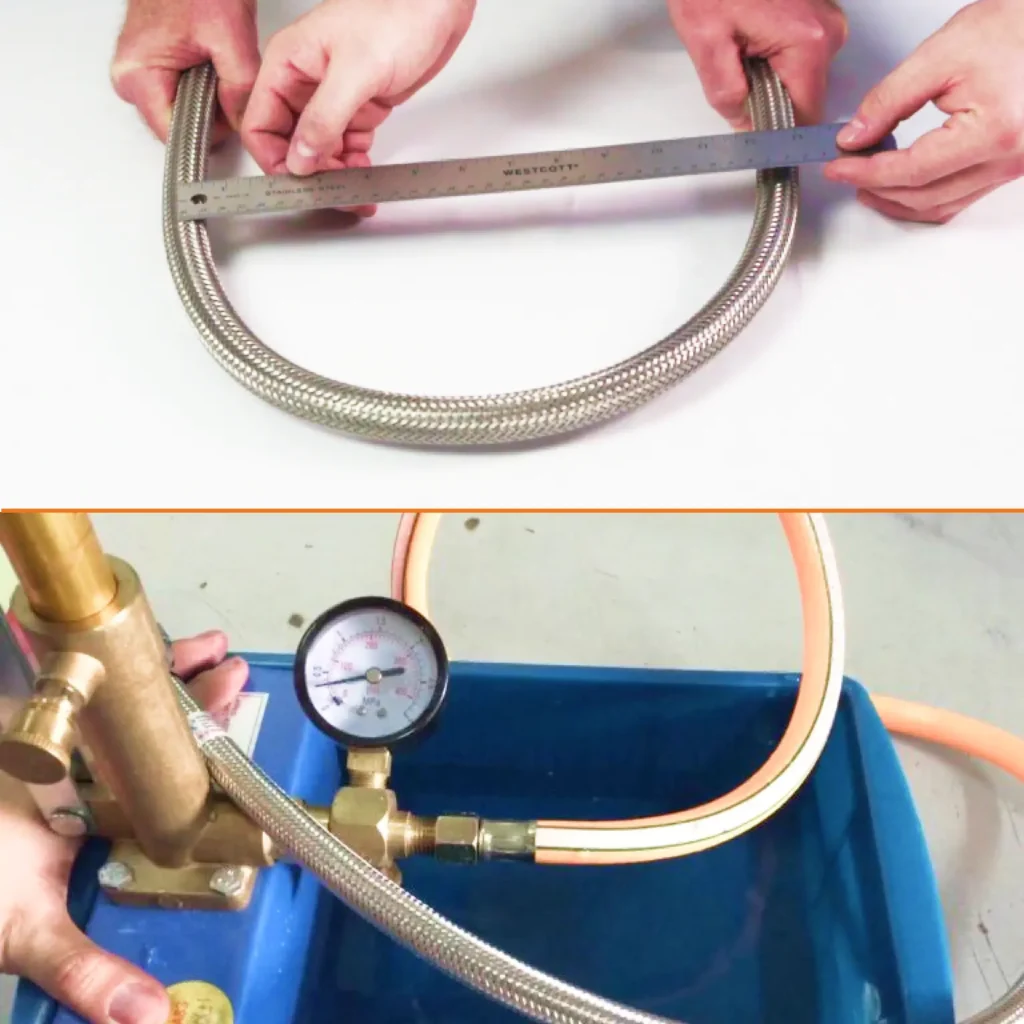

Quality Testing of Stainless Hydraulic Fittings

At Quality Flex, we prioritize the highest quality standards for our stainless steel hydraulic hose fittings. Our production process is meticulously monitored by experienced QC engineers to ensure compliance with international safety and performance standards.

Our in-house laboratory conducts comprehensive tests on all metallic flexible hoses and hydraulic fittings, including hydraulic pressure tests at 1.5 times working pressure and pneumatic tests to ensure leak-proof performance.

- Flex Fatigue Test: Ensures durability through repeated flexing.

- Burst Pressure Test: Determines maximum pressure before failure.

- Bend Radius Test: Evaluates flexibility without damage.

- Flame Test: Assesses fire and heat resistance.

Why Choose Us?

Our stainless steel hydraulic fittings are manufactured to meet the highest industry standards, offering superior corrosion resistance, durability, and performance. Whether you need stainless hydraulic hose solutions for chemical processing, heavy equipment, or industrial applications, QualityFlex provides reliable, high-quality products tailored to your needs.

Contact QualityFlex today for custom solutions and explore our range of steel hydraulic hose products that deliver efficiency, safety, and longevity in even the harshest environments.

SS Hydraulic Fittings Applications

Oil & Gas Industry

Chemical Industry