Stainless Steel Hose Assemblies Installation

Proper installation of stainless steel hose assemblies is crucial to ensure optimal performance and longevity. Incorrect installation can lead to premature failure due to sharp bending near the end connections, stress, twisted mounting, and excessive fatigue. To avoid these issues, it’s essential to follow the correct installation practices.

SS hose assemblies should be installed without sharp bends near the connections, as this can create undue stress on the hose and lead to early wear and tear. Additionally, avoiding twisted mounting and ensuring that the hose is installed without excessive tension or bending will help prevent fatigue and extend the life of the hose assembly.

Refer to the table below for correct and incorrect installation modes to ensure your stainless steel hose assemblies provide reliable service for the long term.

| Right | Wrong | ||

|---|---|---|---|

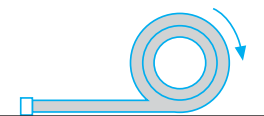

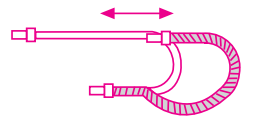

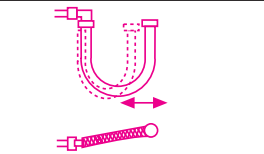

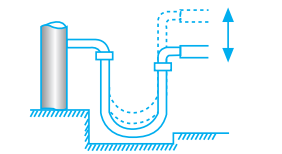

| In order to maintain allowable bending radium, the flexible hoses folded in convolution have to be erected and stretched out for use |  |

Please note that the directly pull one end of folded hose is forbidden. |  |

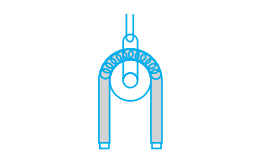

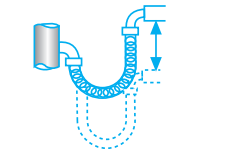

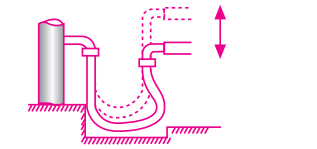

| Use semi-round pulley to maintain allowable bending radium. and stretched out for use |  |

Extreme bending will break up the hose. |  |

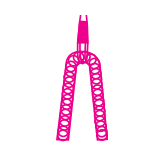

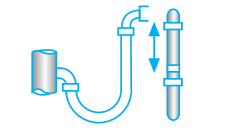

| Apply the rotating trolley, being synchronous with flexible hose, to avoid unsuitable bending |  |

The choice of over-long length will cause unregulated bending |  |

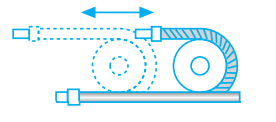

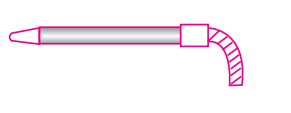

| Apply rigid elbow fitting at the slight bending part in order to ensure the bending radium of hose. |  |

Unsuitable bending will reduce the duration period of flexible hose. |  |

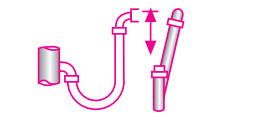

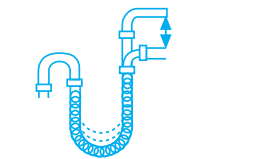

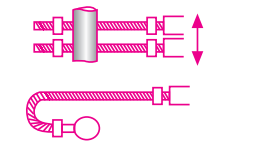

| Use rigid elbow connection with guarantee that the movement of flexible hose at two ends should be on the same line |  |

It can reduce duration period of flexible hose moving in a state of tortuosity. |  |

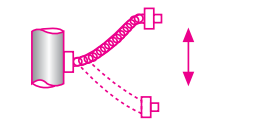

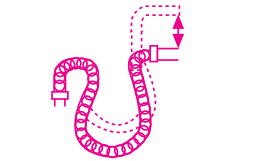

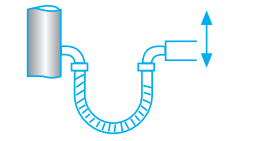

| The movement direction of hose and its installation should be maintained in the same plane |  |

Over-bending will cause damage to the hose. |  |

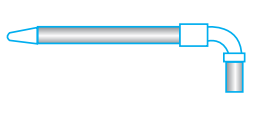

| Use rigid bending at the place of bending to make the hose be in the shape of lineal tubing |  |

It can reduce duration period of flexible hose moving in a state of tortuosity. |  |

| Apply rigid elbow fitting in order to ensure the bending radium of hose when moving. |  |

Too slight bending can cause damage to flexible hose. |  |

| Allowable minimum being radium should be ensured when installing hose. |  |

It is forbidden that too short length of hose is chosen to avoid excessively slight bending. |  |

| Hose should be kept away from other things when moving. |  |

Hose can be damaged when blocked by other things when moving. |  |

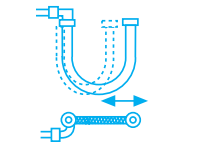

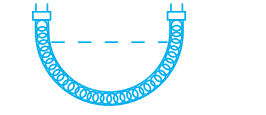

| The movement direction of hose and its installation should be maintained in the same plane. |  |

It can reduce duration period under the condition of hose ends moving in different planes. |  |