Temperature Correction Factor in SS Flexible Hoses

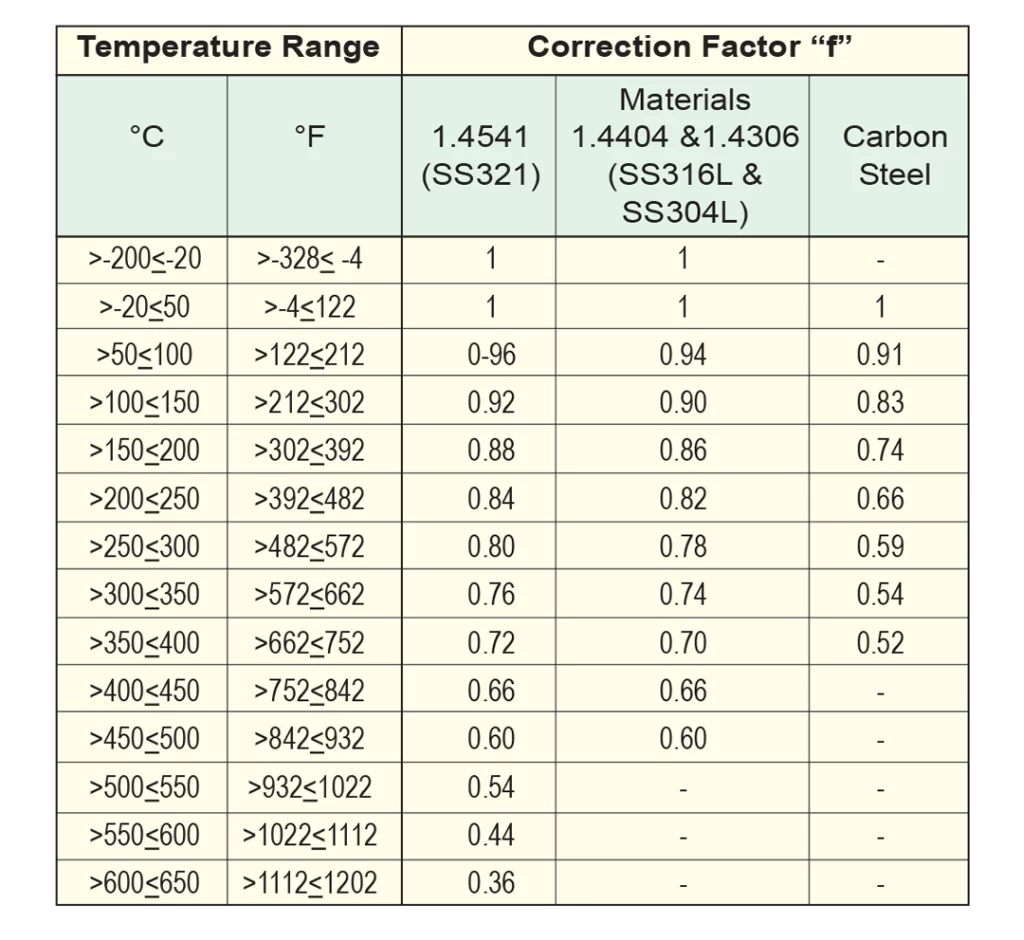

When working with stainless steel hoses at higher temperatures, it’s essential to adjust the working pressure to ensure safety and performance. For SS flexible hoses, the pressure rating provided in Table 1 should be multiplied by a specific correction factor to determine the appropriate pressure rating at elevated temperatures.

For instance, if you’re using a steel braided hose with a nominal bore (NB) of 50 and require a design pressure at 200°C, and the hose material is SS316L, the specified pressure for a 50 NB single wire braid hose (Series A100) is 30 bar. However, due to the high temperature, the correction factor at 200°C is 0.62. This means the permissible working pressure for the hose is calculated as 30 x 0.62, equaling 18.6 bar.

Thus, the recommended design pressure for an SS316L DN50 hose with single wire braiding at 200°C is 18.6 bar. This calculation ensures that your stainless steel hose assemblies perform reliably under high-temperature conditions, maintaining the integrity of your system. Whether you’re using SS hose fittings or other components, always consider temperature corrections for optimal safety and performance.

Need Stainless Steel Hoses?

We’re here to help! Get in touch with us today to inquire about our range of SS hose assemblies and fittings.

Our Products

FAQ

A temperature correction factor adjusts measurements to account for temperature variations, ensuring accurate readings in varying thermal conditions.

Temperature correction is calculated by adjusting the measured value using a correction factor based on the difference between the actual and reference temperatures.

SS hydraulic hoses typically have a temperature rating of -200°C to 600°C, depending on the specific material and construction.